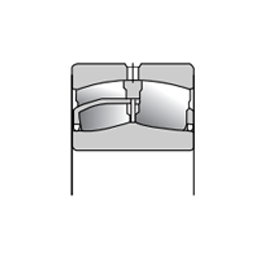

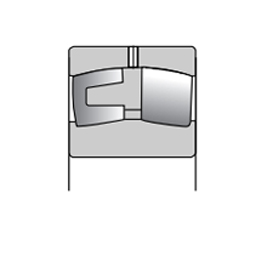

Vibrating mechanical spherical roller bearing

In the process of industrial production, it is often necessary to divide various raw materials (such as ore, coal, stone, etc.) and various primary products (such as cement, salt, monosodium glutamate, etc.) into several levels according to the particle size of the material, or remove the moisture and impurities in it to carry out the next step of processing and improve product quality, which requires the use of screening machinery. Vibrating screen is a common screening machine, and it has a wide range of applications in all walks of life. From mining to metallurgy, from building materials to electricity, from road and bridge construction to food and chemical industry, vibrating screens are working everywhere. It is no exaggeration to say that it is impossible to manufacture a qualified, high-quality product without vibrating machinery. How does a vibrating screen work? And how does it screen the material? We all have the experience that when a car turns, the body of the person sitting in the car leans towards the outside of the turn, which is centrifugal force. The vibrating screen relies on this principle to make an inertial vibrator to work. People install an eccentric body on the shaft and use an electric motor (or other power machine) to drive it to rotate, and then the eccentric body generates an outward (relative to the axis) force. The greater the mass of the eccentric body, the farther it is from the axis, the higher the speed of the shaft, and the greater the centrifugal force. Unlike when a car turns, the circular motion of this eccentric body produces a continuous force along the circumference. This is the vibrator (or exciter), which is installed in the appropriate position of the screen machine in an appropriate way, and the screen machine can be driven to do circular motion, and the circular vibrating screen will be generated.

In addition to the vibration motor, the main accessories of the vibrating screen are the bearings, and the quality of the bearings directly affects the quality of the vibrating screen.